Grasping DTF Printing: A Comprehensive Guide to Direct-to-Film Techniques

Grasping DTF Printing: A Comprehensive Guide to Direct-to-Film Techniques

Blog Article

Ultimate Overview to DTF Printing Strategies for Stunning Fabric Layouts

Embarking on the journey of understanding DTF printing techniques can open up a world of possibilities for creating visually fascinating textile styles. In this guide, we will explore the detailed details of DTF printing, from comprehending the essential fundamentals to unraveling advanced shade methods that can boost your layouts to new elevations.

Understanding DTF Printing Essentials

DTF printing, a procedure that entails moving layouts from an unique film to textiles using heat and pressure, develops the structure of textile printing techniques. This ingenious approach enables for high-grade, vivid styles to be flawlessly moved onto various materials with precision and information. The very first step in DTF printing involves developing or selecting a design that will be printed onto the fabric. This design is after that printed onto a special movie using a DTF printer, which makes use of particular dyes or pigments to make sure shade precision and resilience.

The final result is a magnificent, resilient textile style that is cleanable, adaptable, and resistant to fading. Overall, comprehending the essentials of DTF printing is necessary for grasping this modern-day fabric printing strategy.

Selecting the Right Fabric Products

Having established the fundamental concepts of DTF printing strategies for textile styles, the following important factor to consider exists in picking the suitable fabric materials to complement this innovative procedure properly. The success of a DTF print greatly depends upon the compatibility between the selected textile and the printing strategy. When choosing textile products for DTF printing, it is important to think about the material's composition, weave, and appearance. Fabrics that work well with DTF printing consist of polyester blends, spandex, nylon, and various other synthetic materials. These materials typically have a smooth surface that permits dynamic and thorough prints. Furthermore, the stretchability of these products can fit the heat transfer process entailed in DTF printing without misshaping the layout. It is advisable to avoid all-natural fibers such as cotton or silk, as they might not produce the exact same degree of print quality and toughness. By selecting the appropriate fabric materials, developers can take full advantage of the potential of DTF printing to develop long-lasting and magnificent textile layouts.

Mastering the Printing Refine

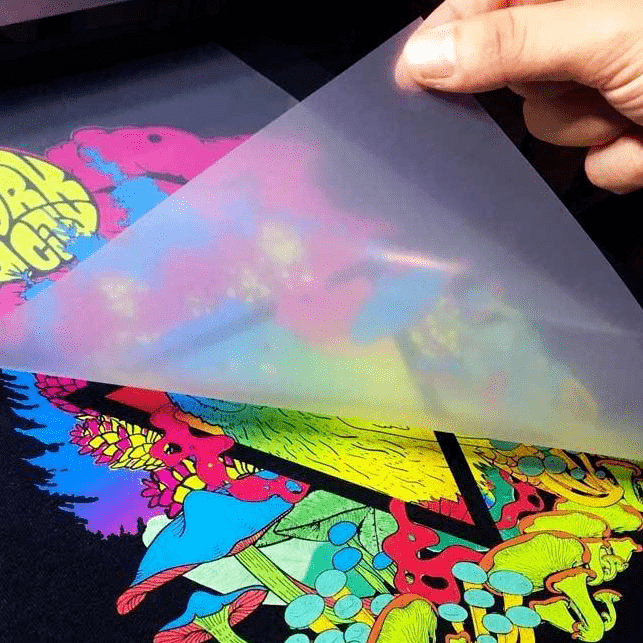

To succeed in DTF printing techniques for fabric styles, understanding the printing procedure is important for accomplishing top quality and regular outcomes. The printing procedure in DTF entails numerous essential steps that need accuracy and attention to detail. Preparing the artwork for printing is essential. This consists of ensuring the layout is properly sized and placed for the textile. Next, the style is printed onto a special DTF film making use of a suitable printer with the right settings to attain ideal shade vibrancy and clarity (DTF Printing). Once the style is published, it is after that transferred onto the material using a warmth press device. The temperature level, pressure, and period of warmth application have to be very carefully regulated to make sure correct adhesion of the style to the textile. In addition, mastering the peeling off process after warmth pushing is vital to protect against any type of damage to the style or fabric. By honing each of these actions in the printing procedure, developers can continually generate spectacular and long lasting fabric layouts with DTF my latest blog post printing strategies.

Enhancing Designs With Shade Methods

Furthermore, explore shade slopes can bring a sense of activity and fluidness to the style. By blending shades flawlessly, a slope result can be achieved, including a modern and dynamic touch to the fabric layout. In addition, utilizing color obstructing strategies can create striking and strong visuals by comparing various solid shades in unique areas of the design.

In addition, integrating metallic or neon shades can give a eye-catching and one-of-a-kind component to the textile layout, making it attract attention and show a feeling of vibrancy. When tactically applied, these color strategies can raise the general aesthetic appeal of textile styles, making them much more exciting and unforgettable.

Troubleshooting Common DTF Printing Issues

After checking out numerous shade strategies to boost fabric designs, it is necessary to address typical DTF printing issues that might develop during the production procedure. Additionally, problems with image clearness and sharpness can occur due to low-resolution photos or incorrect printing techniques. By being mindful of these usual troubles and applying the needed troubleshooting steps, you can enhance the total high quality of your DTF published textile designs.

Verdict

In next page final thought, understanding DTF printing strategies is important for creating sensational textile layouts. With method and attention to detail, one can develop special and gorgeous fabric designs utilizing DTF printing techniques.

Styles))))

DTF printing, a procedure that involves moving layouts from a special movie to textiles making use of warmth and pressure, forms the structure of textile printing strategies.Having actually developed the fundamental principles of DTF printing strategies for textile designs, the next crucial factor to consider exists in picking the proper textile materials to complement this cutting-edge process properly. By selecting the ideal fabric materials, designers can optimize the possibility of DTF printing to create durable and magnificent textile styles.

To succeed in DTF printing techniques for textile designs, understanding the printing process is crucial for accomplishing consistent and high-grade results. DTF Printing. By sharpening each of these steps in the printing procedure, designers can continually create durable and spectacular textile designs with DTF printing methods

Report this page